Conveyor

Conveyors are closed-circuit transfer systems that are used to carry granule or packed loads or tools from one place to another from air or ground. Conveyors are especially used to carry heavy and large materials and commonly preferred since they ensure transportation of many products quickly, efficiently and easily.

Conveyor Types

Depending on industrial branches and needs, there are various types of conveyors. Driven manually or through electric motors, conveyors are manufactured as band, roll, chain, telescopic, flexible, or bucket. According to the manner of application, conveyors are classified as Double-Layer S Conveyor, Aligning-Sorting - Collecting Conveyors, Rotation Conveyor, Vibration Conveyor, and Z Chassis Conveyor.

Fields of Use

Conveyors are mainly used in mining companies, sand pits, agriculture and agriculture-based industry, industrial mounting lines, automotive, food separation, classification and processing lines, bottling/packaging lines, pharmaceutical industry, aviation, printing, wooden - timber production industry.

PGR Drive Technologies provides absolute solutions in conveyor driving with its high-performance, strong, rigid, modular gear units that enable inverter applications.

Conveyor Solutions

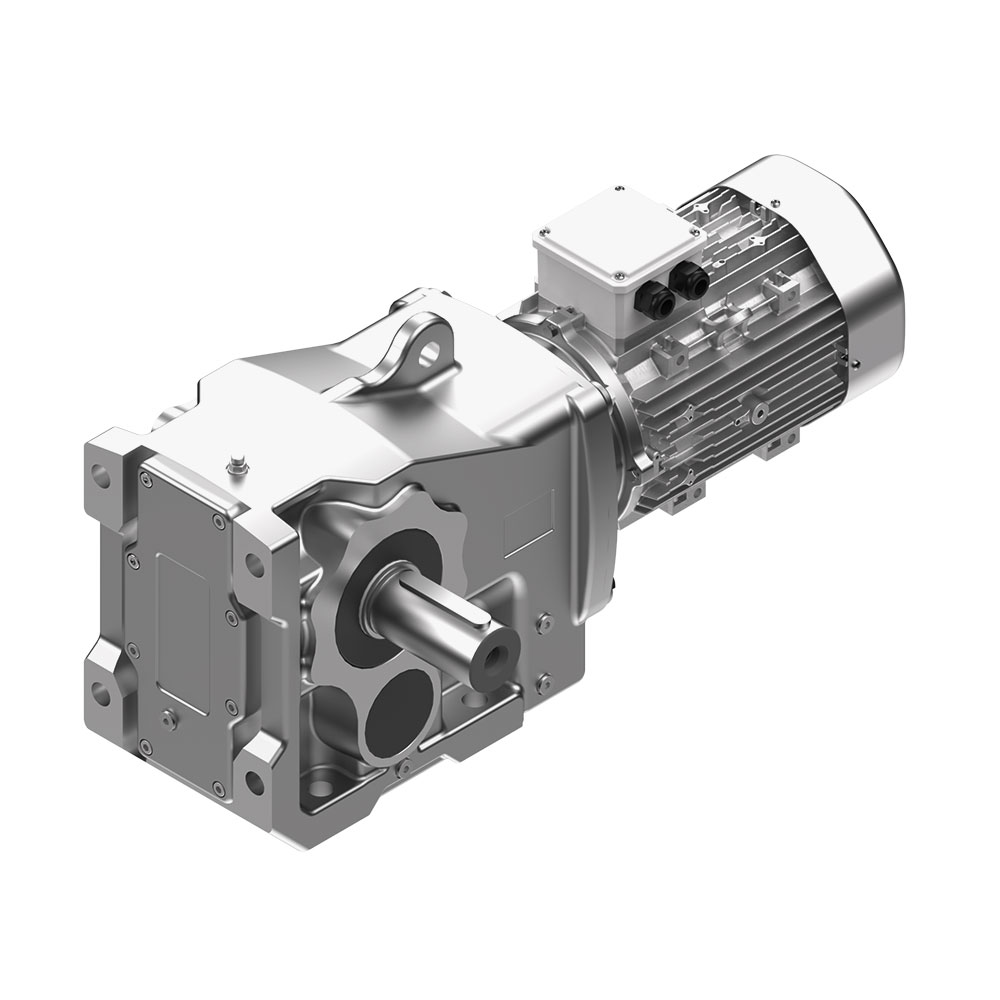

PKD Series

It may be the drive solution in various conveyors used for heavy load transfer where movement is to be directed at 90°.

- Helical bevel gear units with 90° input and output axis range.

- Casing with feet, flange F options.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm and Platforms,...).

- Bodies are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

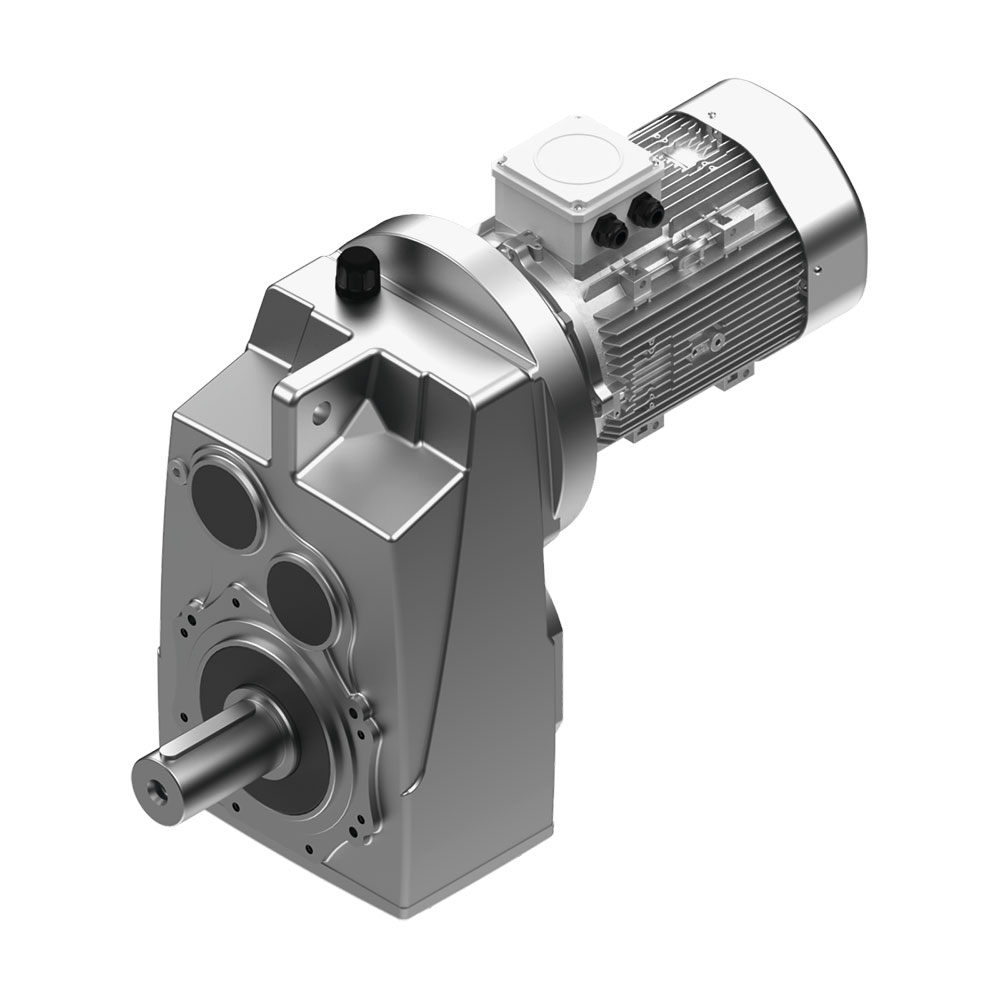

PD/PM Series

PD / PM series parallel shaft mounted gear units produced with hollow shaft or solid shaft are commonly preferred in conveyor drive systems.

- Helical gear units with parallel axis input and output.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Rubber buffer for torque arm, ...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

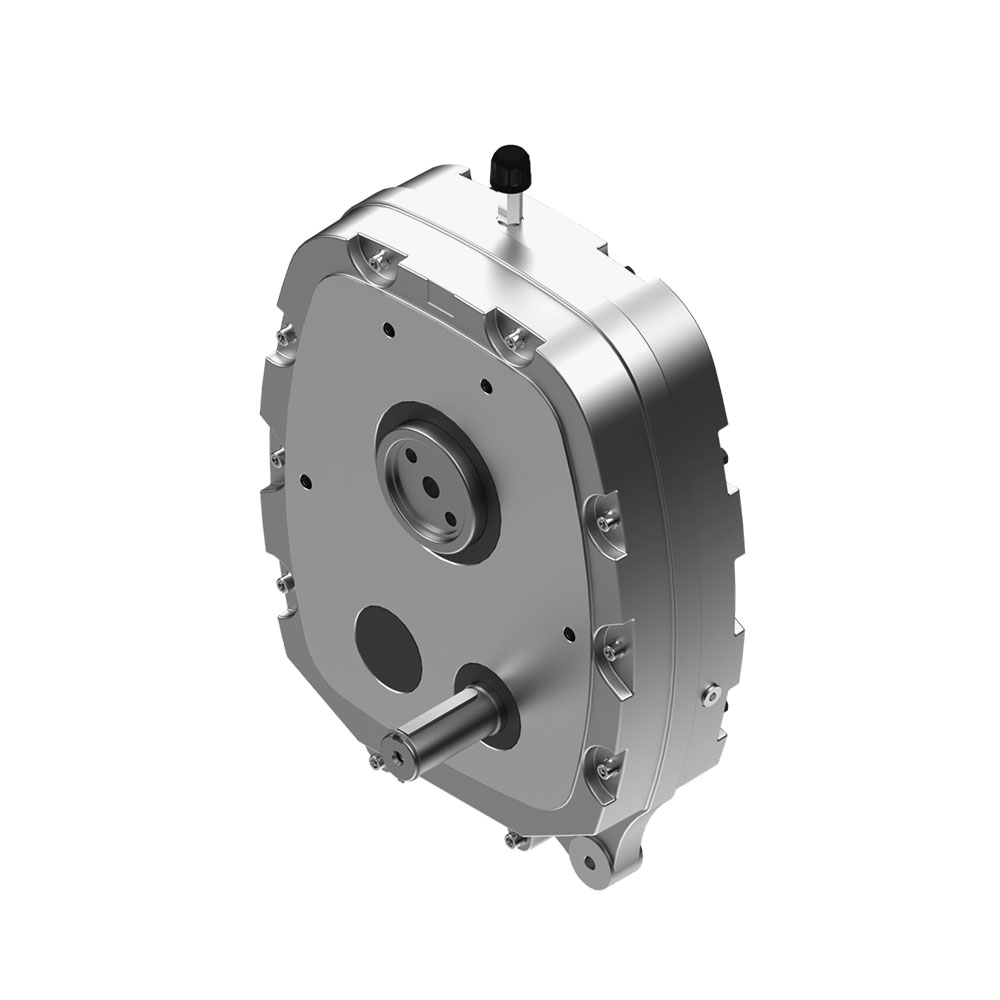

Pt/A Series

Preferred in various transfer systems thanks to their wide reduction ratio, compact structure and easy maintenance, PGR Drive Technologies Pt/A Series gear units can be driven with belt-pulley or chain mechanisms.

- Helical gear units with parallel axis input and output.

- A rigid case structure consisting of two components.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Free input shaft enables driving.

- Different output options available (Hollow shaft, With shrink disc, ...).

- Mounted with torque arm.

- Cases are manufactured from cast iron (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

P Series

P series gear units developed for belt-pulley, chain-driven elevator conveyor systems and drive systems operating in hard-to-work areas stand out thanks to their easy maintenance features.

- Helical gear units with parallel axis input and output.

- A rigid body structure consisting of two components.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Free input shaft enables driving.

- Different output options available (Hollow shaft, With shrink disc, ...).

- Mounted with torque arm.

- Bodies are manufactured from cast iron (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be met.

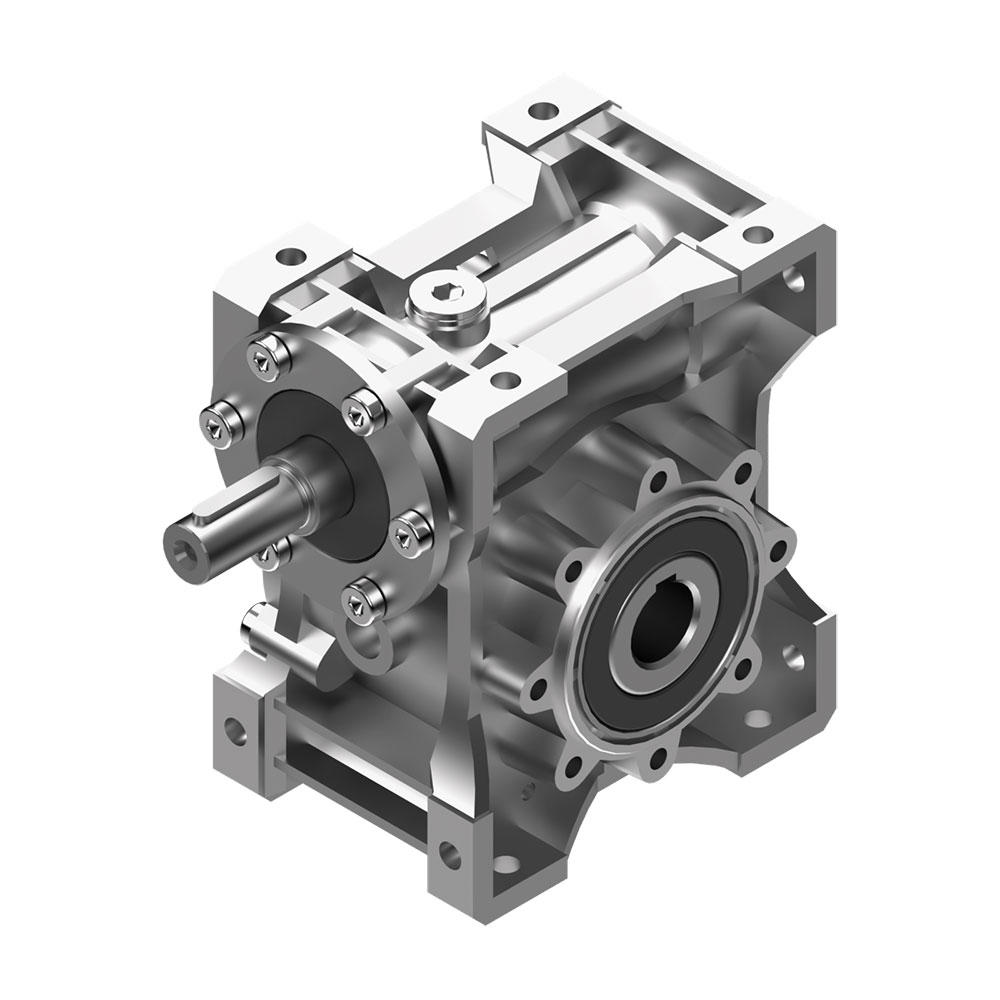

PMRVPLUS / PRVPLUS Series

Offered for drive systems with low moments and regular loads, worm gear units stand out with their light, modernly designed bodies with high strength, as well as silent operation.

- Worm gear units with 90° input and output axis range.

- Foot- and flange- mounting available with a single case.

- Rigid case structure and suitable for heat transfer.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options available (PAM B5, PAM B14, ...).

- Different output options available (Solid shaft, Hollow shaft, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm, ...).

- Worm screws are made of 16MnCr5 case-hardening steel, worm wheels are made of CuSn12Ni-C bronze material.

- Cases are made of ADC-12 aluminum injection up to 105 body case and peak cast (GG 20-25) for over 110 body case.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.