Recycling

Recycling is an important process to protect natural resources, reduce waste and minimize negative effects on the environment. In this process, reducers play an important role in keeping recycling equipment running efficiently and guiding material handling processes.

Gearboxes Used in the Recycling Industry

Recycling is an important process to protect natural resources, reduce waste and minimize negative effects on the environment. In this process, reducers play an important role in keeping recycling equipment running efficiently and guiding material handling processes.

Which Gearboxes Are Used in the Recycling Industry?

- Conveyor Gearboxes: Gearboxes are of great importance in conveyor systems used for the transport and classification of waste materials. These gearboxes must be able to produce high torque at low speeds and must be resistant to continuous operating conditions. PGR offers strong and durable gearboxes for conveyor systems with PA/PF, PSH, PD/PM, PMRVPLUS/PRVPLUS and P series.

- Bale Press Gearboxes: Bale press machines used to compact and bale recycling materials are processes that require high torque. Gearboxes enable these machines to produce high torque at low speeds. PGR’s specially reinforced ball bearing PA/PF series and PCD series are our gear units used in bale press processes; they offer high performance, energy efficiency and reliability.

- Grinder Gearboxes: Gearboxes play an important role in grinding machines used for grinding or shredding recycling materials. These machines require high torque at low speeds. PGR's P and P/tA series provide advantages such as high torque generation, precise speed control and long life.

Why is it Important to Use Gearboxes in Recycling?

The use of gearboxes in the recycling industry brings many important advantages. Here are some reasons why it is important to use gearboxes in recycling:

- Efficiency and Performance: Gearboxes keep recycling machines running efficiently. Thanks to the high torque generation, it is possible to process waste materials more effectively. Gearboxes enable machines to perform at low speeds.

- Energy Efficiency: PGR's gear units specially designed for recycling provide energy efficiency. Thanks to high technology and optimized gear designs, energy resources are saved. This both reduces the environmental impact and reduces the energy costs of businesses.

- Durability and Reliability: The recycling industry is faced with intense workload and challenging working conditions. It is therefore of great importance that the gearboxes are durable and reliable. PGR's quality and robust products provide long-lasting use and low maintenance requirements. This ensures uninterrupted operation of businesses.

- Environmentally Friendly Approach: The recycling industry has a critical role in environmental protection and sustainability. The use of gearboxes allows for more efficient processing of recycling materials and more productive use of resources. This reduces the negative effects on the environment and aims to leave a clean environment for future generations.

In the most succinct form, we can say that; The use of gearboxes in the recycling sector provides many advantages such as efficiency, energy saving, durability and environmental protection. PGR's specially designed gearboxes allow recycling machines to perform at a high level.

Recycling Solutions

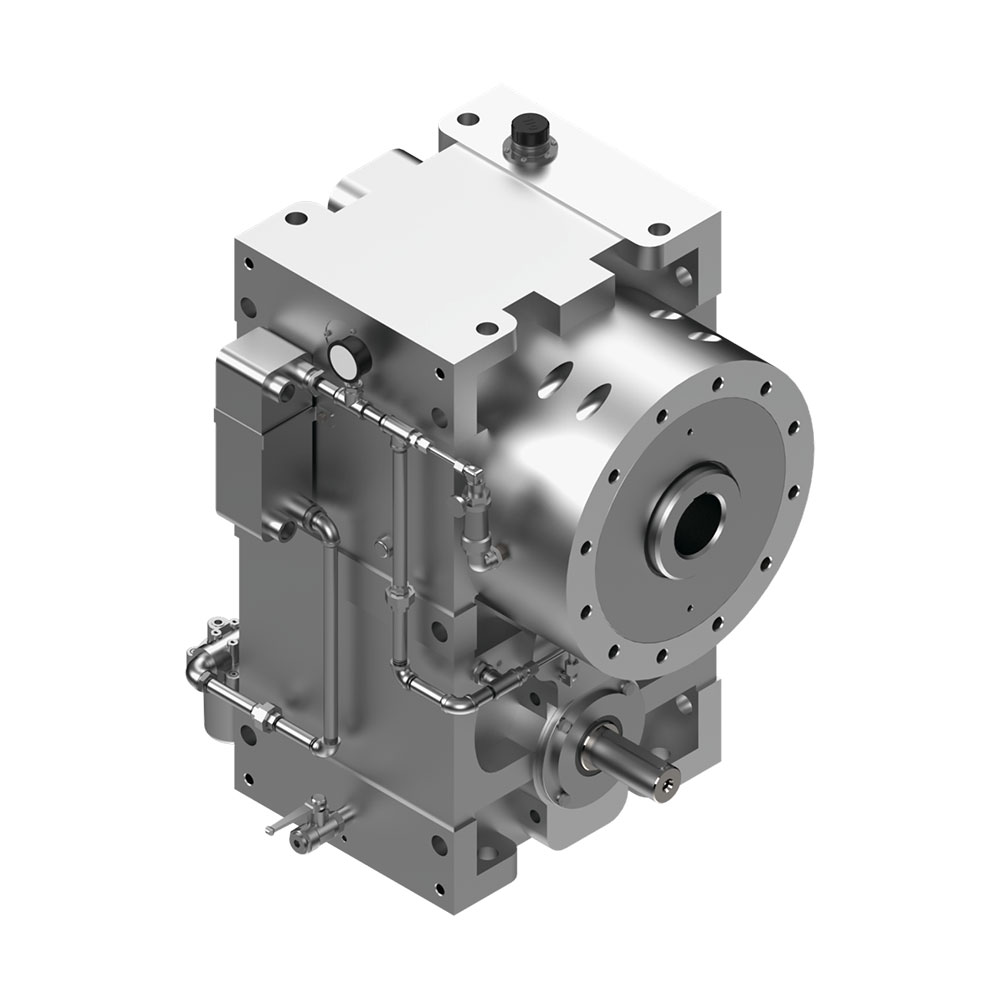

PEX Series

PGR Drive Technologies provide solutions with PEX series extruder systems with high axial and radial forces thanks to their rigid, strong case and wide reduction ratios.

- PEX series are designed for extruders with single and twin screws.

- They are available in 12 different case sizes with 2 or 3 stages.

- 8-30 reduction ratio in 2 stages

- 10-50 reduction ratio in 3 stages.

- Since input and output shafts have long distance, electric motor and drum can be easily mounted.

- Cases are manufactured from cast iron (GGG 50-60).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- E series “294” bearings are used for axial load of extruder screw.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

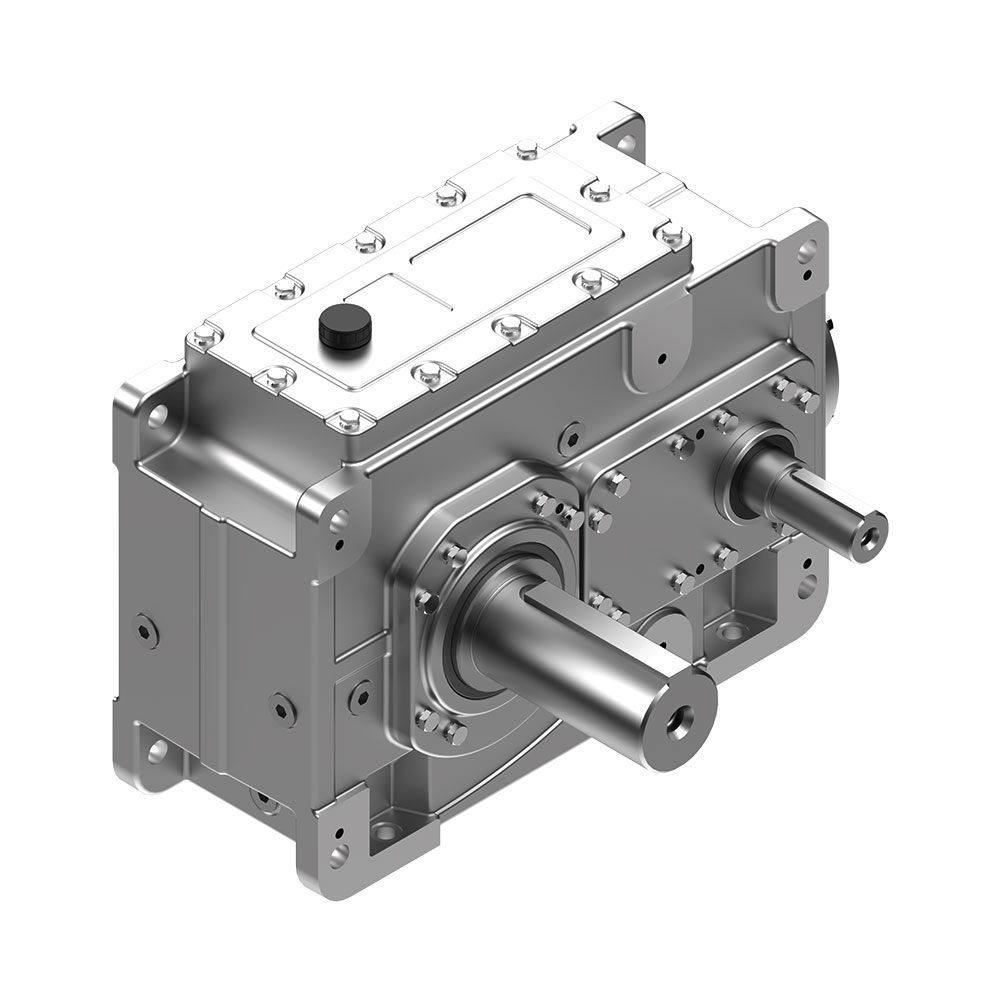

PH/PB Series

Industrial type gear units operate especially under heavy working conditions, have rigid case, bear high moments up to 480000 Nm and stand out with silent operation and easy maintenance features.

- Helical - bevel gear units with parallel axis input and output or 90° axis angle.

- Casing with feet, flange F options.

- A rigid structure in case.

- Gear units used to meet needs for high power under heavy working conditions.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options available (IEC, W, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting options available ( B5 flange, Torque arm platform,...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

PL/PLB Series

PGR Drive Technologies provide solutions in planet gear units with PTO, IEC, parallel shaft input options which offer high reduction ratio in small volumes in drive systems with heavy and variable loads thanks to their compact and modular structure up to 850000 Nm of moment values.

- Gear units with coaxial input and output or 90° axis angle.

- Casing with feet, flange F options.

- A rigid and modular structure in case.

- Compared to other gear units, higher moment values can be met with smaller body sizes.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (IEC, Hydraulic Motor mounted, Servo motor mounted, ...).

- Different output options available (Hollow shaft, Shrink disc, DIN form splined,...)

- Cases are manufactured from cast iron (GGG 50-60).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

Please Contact Us For PL/PLB Series General Parts List.